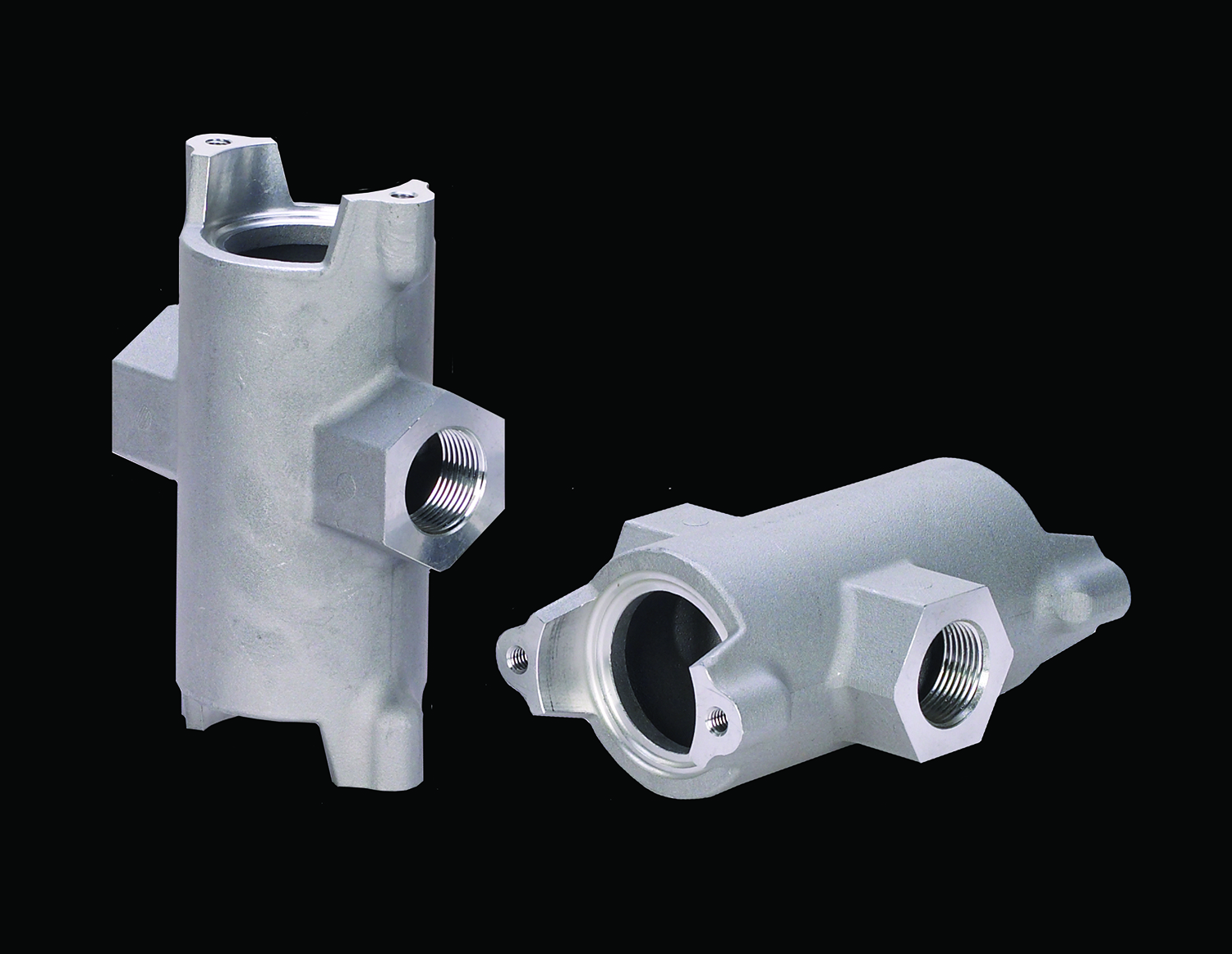

PERMANENT MOLD (Gravity Casting or Low Pressure Casting)

Molds are made of metal and coated with a die release. Molten metal is poured into the mold using gravity or very low pressure to fill the cavity. When solidified, the mold is opened and parts are ejected or removed by hand.