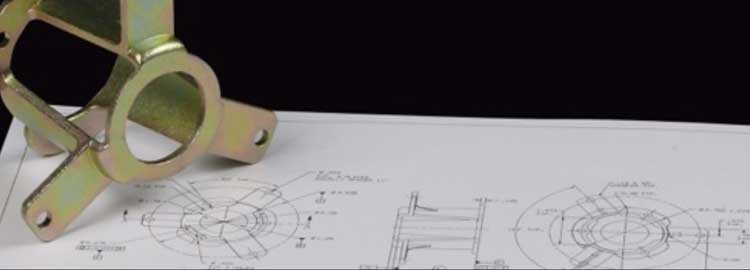

Pressure Vessel Castings

CIC specializes in Pressure Vessel Castings.

We provide all types of pressure vessel castings, which is a process where molten metal is injected at high pressure or poured into a mold containing a hollow cavity the shape of the part to form an object to a desired shape. The solidified part is known as a casting which is broken out or ejected from the mold to complete the process. Casting is most often used for making complex shapes that would otherwise be difficult or cost prohibitive to produce by other methods.

The cast metal part is removed from the mold either by injection or destruction of the mold.

Most common castings alloys can be cast using expendable molds. Reusable molds depend on the alloy melting points. If the melting point of the alloy is higher than the mold melting point, then reusable molds are not an option.

To complete the process after the pressure vessel castings parts are cooled, gating is removed and then they are typically ground and cleaned, and machined if necessary, to produce a semi-finished or finished part.

Benefits of Pressure Vessel Castings

- The pressure vessel castings shapes that can be produced are almost limitless.

- With the correct pressure vessel castings design and process many parts can be combined into a single part &emdash; helping reduce costs by reducing or eliminating machining, by providing assembly, as well as by reducing the number of components in inventory and other associated costs.

- Design flexibility. Castings allow you to choose from many alloys as well as have flexibility for internal and external configurations to suit your particular needs. Net shape production is sometimes achievable so that the parts are usable as cast. However, to achieve many close tolerances, threads, or surface finishes machining is required. CIC can help minimize the need for expensive secondary operations by choosing an optimal casting process.

- Elimination of material waste. pressure vessel castings are cast to size.

- The pressure vessel castings is usually the most cost-effective method to produce complex or large parts for prototype quantities to medium and high-volume quantities.

The casting process may vary based on production volume and casting tolerance capability of the process. CIC helps their customers "engineer savings" by providing cost effective pressure vessel castings design solutions, sourcing and warehousing.

CIC provides cost efficient die castings, semisolid castings, shell castings, permanent mold castings, sand castings, investment castings, centrifugal castings and prototype castings.

Each casting type and alloy has pros and cons regarding cost, volume production, metallurgical quality, dimensions held, reliability and competitiveness.

Casting characteristics to consider include cost, strength, hardness, density weight limitations, bearing qualities, if needed including galling resistance, machinability, weldability, brazabilty, abrasion resistance, corrosion resistance, oxidation resistance, fatigue properties, resistance to cracking, electrical conductivity, magnetic properties, thermal conductivity and other engineering or technical attributes.

Working with CIC ensures that all of your pressure vessel castings requirements are considered for your application.

CIC's pressure vessel castings consulting, quality component manufacturing, supply chain management and warehousing options exceed industry standards and provide the best overall value and savings.

CIC supplies many special casting alloys as well as many more common alloys as listed below, including aluminum, magnesium, beryllium copper, nickel, titanium, refractory metals, gray iron, ductile iron, carbon steel, alloy steels and stainless steel as well as other less common alloys.

- Aluminum: A360, A380, A356, A319, Tenzalloy, A713, A413, A319

- Brass/Bronze: C95200, C95400, C95500, C95800, C90800, C93200 (SAE 660), C83600, C84400, C83400

- Iron: Class 30 Gray Iron, 65-45-12, 80-55--06, 100-70-03 Ductile Iron, A532 Abrasion Resistant, Austenitic Ductile Iron (ADI), Magnesium: AZ91

- Nickel: Inconel, Hastelloy, Monel

- Stainless Steel: CF8 (304), CF3 (304L), CK20 (310), CF8M (316), CF3M (316L), A297 Heat Resistant, A351 Corrosion Resistant, 17-4PH, 15-5PH, Duplex, CA15 (410)

- Steel: 4340, 8620, WCB, WCC, LCB, CA6NM, 1020, 1030, 1040

- Titanium: Ti-6Al-4V

- Zinc: Zamak 3, 5, 7, ZA8, ZA12

CIC provides pressure vessel castings and other types of castings for a wide range of industrial OEMs including transport (railway, shipping, aircraft and aerospace), heavy equipment (construction, mining, farming), plant machinery (paper, petroleum, food), hardware, defense (munitions, vehicles, supporting equipment), and household (appliances, gardening equipment, furniture, fittings), machine tools, electrical machines (motors, generators, pumps, compressors), municipal (pipes, joints, valves, fittings), industries.

CIC provides pressure vessel castings in Missouri, Illinois, Kentucky, Tennessee, Arkansas, Kansas, Nebraska, Iowa, Oklahoma as well as many other major manufacturing areas in North America.

Contact us for your pressure vessel castings requirements, or consultation and quotation now!

Review our casting types including pressure vessel castings.

Products & services offerings including pressure vessel castings.

In addition to pressure vessel castings CIC offers forgings, metal forming, plastics and other component manufacturing, supply chain management and warehousing.