SEMI-SOLID/SQUEEZE CASTING

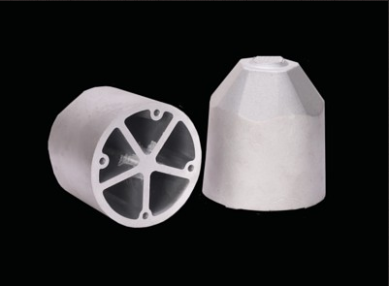

Molten metal is cooled to about 50% of its liquid temperature forming a special globular structure. The metal is then injected at low velocity into a metal die where it cools to a solid and then ejected. Squeeze casting uses molten metal injected into a metal die and held under high pressure while solidification is in process.